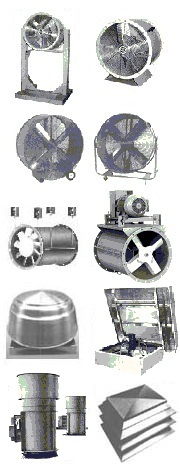

Industrial axial fans,

Canada Blower OEM

blowers, ventilators, high temperature fans and blowers, centrifugal

radial

and axial propeller fans, roof and wall exhaust and supply fan, inline

blowers

and ventilators.

FANS MALL

FANS MALL

American Blower Company has gone through many years of experience in the design and construction of power roof ventilators.

American Blower hooded power roof ventilators are suggested for use in commercial and industrial applications including factories, warehouses and large commercial buildings. There are fan types offering belt and direct driven propellers, exhaust, supply or reversible air movement and filtered supply air. Combinations of these various types can be used and still maintain a uniform and attractive rooftop apperance. The fan hood can be pivoted for roof top access to the fan components.

These hooded roof ventilators are available in wide range of sizes and capacities: with fan blade diameters from 10" to 84" and capacities ranging from 500 CFM to appr. 100,000 CFM. Fans of this type are quite efficient, dependable and require relatively little maintenance.

Canada Blower roof ventilators provide cost-effective, general purpose ventilation of commercial buildings, as well as a large variety of industrial applications. Direct and belt driven models are available with adjustable pitch cast aluminum impellers or fixed pitch impellers constructed of fabricated steel or cast aluminum to meet specific application requirements.

The American Blower PBH PRVs utilize a cross-frame to support unique bearings and shaft assembly. This stationary shaft mounts on the cross-frame member and power is applied directly to the prop hub in the same plane as the bearings. This reduces bearing load and substantially increases the bearing life. Fan bearings are permanently lubricated and sealed and have an L-10 life exceeding 300,000 hours. All roof exhaust fans are available with such fan accessories as reversible wheels, roof curbs, protective coatings, safety guards, spark-resistant and explosion proof constructions, and many other useful features.

High temperature; high pressure blowers and fans, pressure blowers, heavy duty industrial process fans and blowers.

Call

us today: 1-866-225-6937 E-mail: blower@industrialpressureblower.com

ventilating.com fanblower.com highpressureblower.net industrialblowerfan.com industrialfanblower.net industrialfanblower.com pressureblower.net northernindustrialsupplycompany.com industrialpressureblower.com tenderall.com chicagoblowercanada.com cbblower.com buffaloblower.com buffalofan.com nis-co.com canadianblower.com olegsystems.com canadablower.com abbblower.com acmefan.net industrialblower.net fansandblowers.net americanblower.net barryfan.com cincinnatifan.net canadafans.com barryfan.net

Canada Blower Axial Fans:

Like the centrifugal fans, the AMCA standard addressing axial fan drive arrangements is also an ISO standard. The choice for direct drive axial flow fans is Arrangement 4.

Arrangement 4 is direct drive blower where the impeller is overhung on the motor shaft. There are no bearings on the fan and the motor is mounted on a base or integrally mounted to the fan housing.

Axial Belt Drive Fans:

For axial flow belt drive, your definition is Arrangement 9. In this fan arrangement, the impeller is overhung on a shaft with two bearings mounted either upstream or downstream of the impeller. The motor is mounted to the fan casing or on a base that is integral to the fan casing.

Here are the three basic variations of axial flow fans, which all generally have the same performance characteristics.

Propeller Fans:

Propeller fans are the most common type of fan that most of us are familiar with. You've probably seen them in your office or home in the form of an air circulator fan. (It could be a ceiling fan, a desk fan, or a pedestal fan.) It has a propeller and it keeps you cool in warm weather.

Canada Blower uses the same type of propeller fan, but it's called an RFS fan panel or wall panel fan. Canada Blower AXPR ventilator model has fiberglass housing and fiberglass propeller blades. It's primarily used to vent out noxious gasses from chlorine storage rooms or wastewater treatment plants.

Tubeaxial Fans:

Tubeaxial fans have the same wheel design as propeller fans. However, they are mounted in a cylindrical tube or a duct, and are often called duct fans. Canada Blower tubeaxial fans employ a variety of fan propeller designs. Ventilators are designed for use with duct applications, and they are more versatile than panel fans by virtue of their construction. The fans are also more ductable for ventilation of industrial process.

Canada Blower Tubeaxial fans are able to handle up to four inches of static pressure, and low to high flows accommodate medium pressure. Wall panel fans, on the other hand, won't see more than fractional static pressures because they're not ducted.

Vaneaxial Fans:

Vaneaxial fans aren't used as much as they were in the past. They are essentially the same as a tube axial fan, except they have vanes located on the discharge side of the impeller. The function of those fan vanes is basically to recover lost energy or rotation. Canada Blower vaneaxial fans have mostly been replaced with more efficient centrifugal mixed flow fans.

Canada Blower Vaneaxial fans are normally duct mounted inside a building. You can also use them for ventilation. For example, when installed on a roof with a stack cap or damper, you can use them for general exhaust away from the inside of the building and up into the atmosphere.um discharge.

Buffalo Blower Co. offers a wide variety of products and services for industrial air handling applications.

Fume hood exhaust Canada Blower fans are not intended as substitutes for proper pollution control ventilation equipment, but rather a means to exhaust low concentrations of potentially toxic fumes out of and away from occupied spaces. With fume hood exhaust fans, the technology of high velocity and high dilution discharge can be applied to a variety of our standard air moving ventilation products, with many fan sizes to choose from, in direct drive or belt driven fans. These choices exist in a broad line of AMCA certified, high quality air moving fan equipment. Typical Buffalo Blower fan applications include research / development, petrochemical, pharmaceutical, hospital / medical, biotech, industrial processes, and school and university laboratories.

Fan / Blower / Ventilator Products:

Centrifugal fans

Axial fans

Ventilating fans

Roof exhausters

Panel fans

Fume exhaust fans

Fiberglass fans

Industrial exhausters

Heavy duty fans

Pressure blowers

Custom engineered fans

Heating and cooling coils

Air preheater coils

Custom air handling units

Make-up air units

Industrial sound attenuators

Fan Replacement parts